Removing chromium 6

Need to remove Chromium 6? This chromium compound is a hexavalent form, known to pose serious risks in many industrial environments. This chemical compound is recognized for its excellent corrosion-resistant properties, making it widely used in industries such as metalworking, aerospace, and the production of paints and coatings.

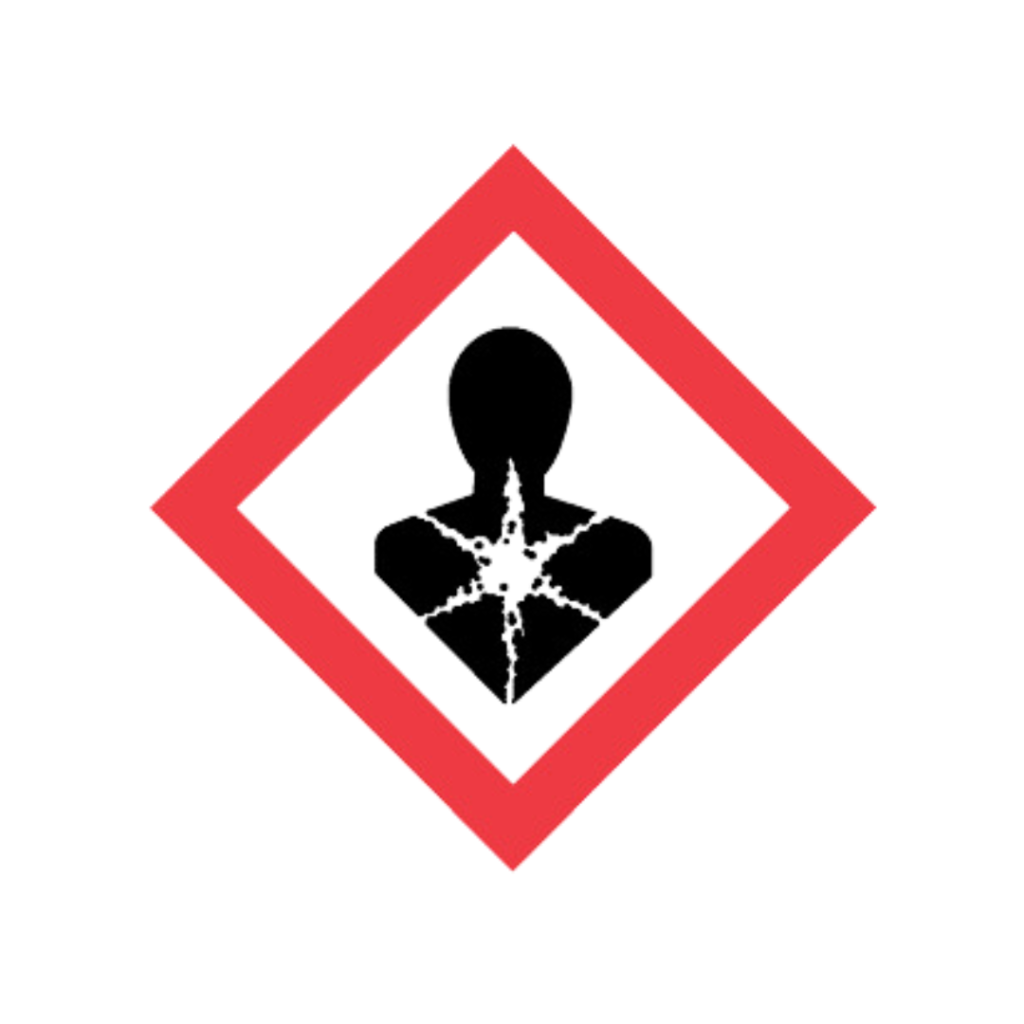

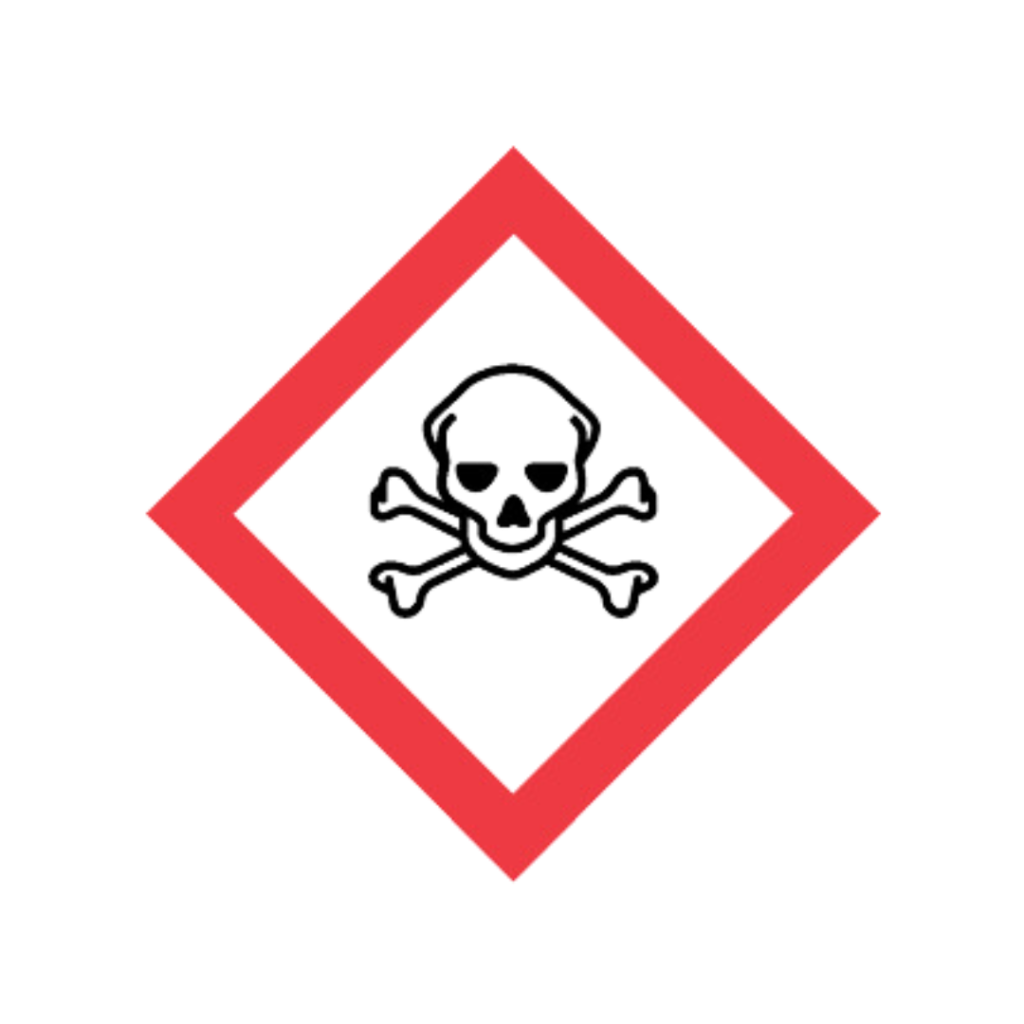

However, the downside of Chromium 6 is its significant impact on the health of your workers and the environment. Exposure to this substance puts your employees at increased risk for severe health conditions, such as:

- Lung cancer

- Respiratory issues

- Skin irritations

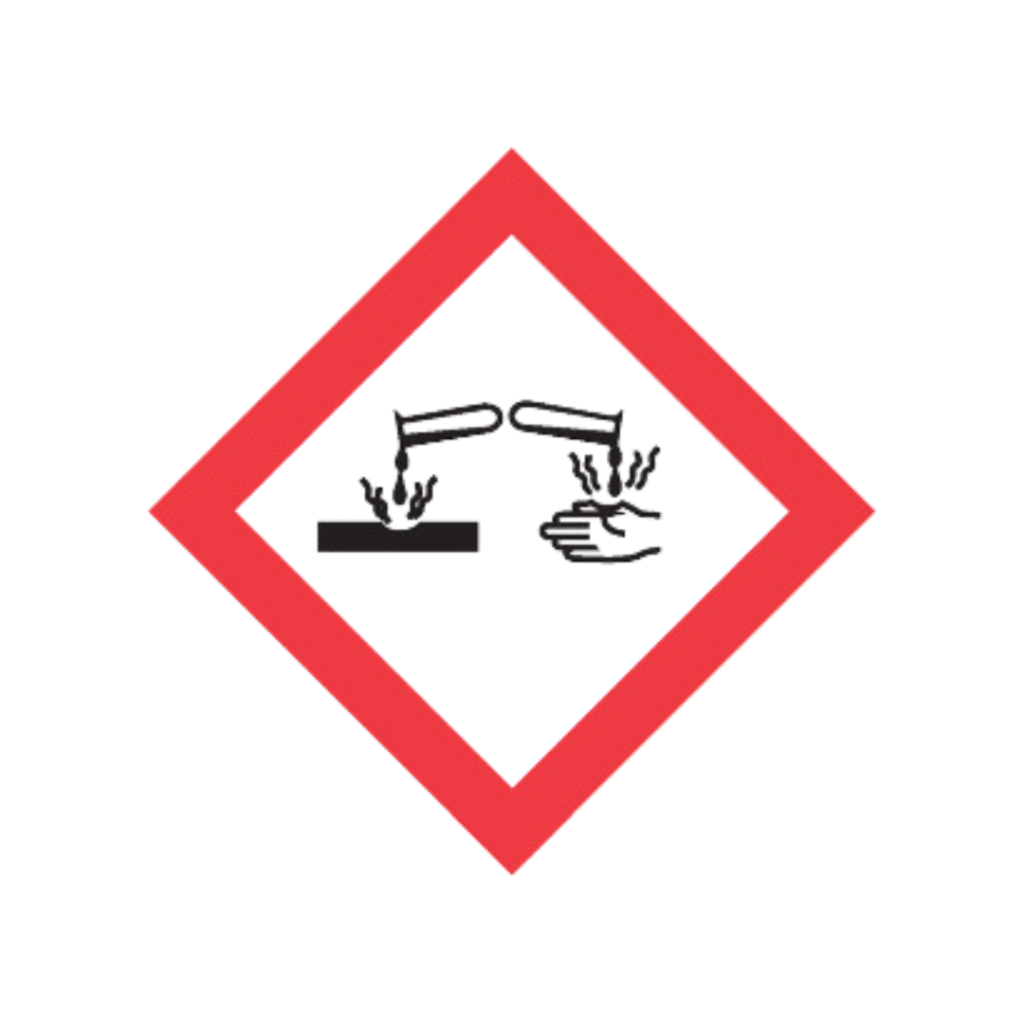

In addition, Chromium 6 can cause substantial environmental harm, especially when it enters water or soil

The risks of removing chromium 6

Removing paint or coating containing Chromium 6 comes with significant risks. Traditional methods for removing Chromium 6-laden paints or coatings, like sanding, often generate harmful dust that poses serious health risks to employees. These methods also entail considerable costs due to the required safety measures and the cleaning of the workspace.

Tackling chromium 6? We offer the solution!

At Pinovo, we understand the challenges your company faces when dealing with Chromium 6. That’s why we offer an innovative solution that not only significantly reduces risks but also boosts efficiency: the Pinovo vacuum blasting machine.

Why is the Pinovo blasting machine suitable for Chromium 6 removal?

Closed system operation: Pinovo’s closed system captures all dust particles and paint residues immediately during the removal of Chromium 6 coatings. This minimizes exposure to hazardous substances for your employees and prevents the spread of chromium in the environment.

Safety first: With the Pinovo machine, you ensure the safety of your employees. The system prevents harmful dust particles from being released. Combined with the appropriate protective equipment, this makes the working environment much safer. Pinovo also offers a training program to ensure your workers face as little risk as possible. This training covers how the blasting machine operates and how to use it in the safest way possible.

Save sosts and work faster: In addition to enhanced safety, the Pinovo blasting machine offers significant benefits in terms of efficiency. The system works quickly and effectively, allowing projects to be completed in less time. Moreover, you save on cleaning costs and reduce the downtime of your production line.

Environmentally friendly & sustainable: The Pinovo blasting machine benefits not only your business and employees but also the environment. Its closed-loop system prevents hazardous substances from entering the environment, contributing to sustainable business practices and compliance with environmental regulations.

Need technical advice?

Would you like to learn more about this application and whether the Pinovo vacuum blasting machine is suitable for your specific project? Please feel free to contact us. We’ll be happy to discuss the options with you to help manage any potential hazards. Together, we’ll ensure that your company has the right ATEX tools to execute your project successfully. Choose safety; choose Pinovo. Additionally, you can rent ATEX blasting machines from us, including the Pinovo blasting machine.