Dust free blasting

Your challenge is our solution. Dust-free blasting is essential in many industries to ensure health, safety, and productivity. Whether you work in the food industry, offshore, or petrochemicals, the release of dust and hazardous substances like chromium-6 poses significant risks. Pinovo’s innovative solutions eliminate these challenges, creating a safe and efficient work environment.

The challenge: why dust-free blasting is necessary

Dust and hazardous substances can lead to:

- Food contamination in the food industry, potentially causing production downtime.

- Explosion risks from dust clouds in petrochemical and offshore environments.

- Machine damage caused by dust particles in precision equipment.

- Inefficiency and delays when parallel operations are not possible.

The solution: dust-free blasting with Pinovo

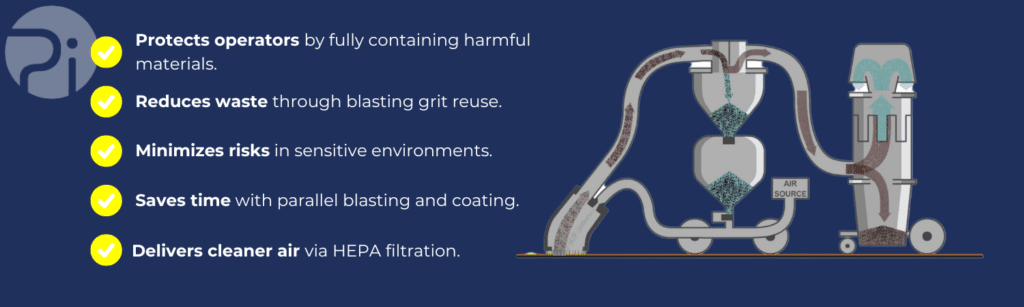

Our dust-free blasting solutions offer unique advantages:

- ATEX-certified: Safe to use in explosive environments.

- Sustainable: Prevents the spread of harmful substances and protects the environment.

- Efficient: Allows blasters and coaters to work simultaneously without interruptions.

- Superior preparation quality: Ensures excellent coating adhesion, maximizing asset lifespan.

Take the first step toward a safer workspace – Request your demo today!

How does dust-free blasting work?

Pinovo’s enclosed system captures dust immediately and prevents dispersion. The process includes three steps:

- Application of blasting media: Media is applied to the surface under controlled pressure.

- Immediate capture: All released particles are instantly collected in a vacuum system.

- Safe disposal: The waste is filtered and safely disposed of.

This approach ensures a clean and safe working environment, ideal for sensitive or explosive areas.

Applications of dust-free blasting

Pinovo’s dust-free technology is suitable for various industries:

- Food industry: Perform maintenance without contamination risks or production downtime.

- Offshore & petrochemicals: Safe blasting in ATEX zones without explosion hazards.

- Shipbuilding: Fully control hazardous substances like chromium-6.

- Factories and workshops: Save time and costs by enabling parallel operations.

“Including all activities, from scaffolding to sheeting, blasting, cleaning and painting, the use of PiHabs has increased our overall efficiency by 100%. It’s also better for the operators from a health and safety perspective”

- GER VAN HEESCH, supervisor protective coatings at PCC / Verwater Group B.V.

Why choose Pinovo?

Choosing Pinovo means:

- Expertise: Years of experience in dust-free technologies.

- Support: Tailored technical advice and training.

- Reliable solutions: Designed for the toughest industrial applications.

Technical advise and training

At Pinovo, we don’t just provide innovative tools—we ensure you can use them to their full potential. Our specialists offer:

- Tailored Technical Advice: Get expert guidance on choosing the right solutions for your industry and unique challenges.

- Comprehensive Training Programs: Learn how to implement dust-free blasting efficiently and safely, maximizing both productivity and safety.

By combining our expertise with your operational goals, we deliver results that go beyond expectations. Ready to take the next step?