Project: addressing safety risks in the port of Rotterdam

The challenge: contaminated coating on natural gas pipelines The natural gas pipelines at a chemical plant were coated with a layer contaminated by chromium-6, a hazardous substance commonly found in some industrial coatings. Chromium-6 is notorious for its severe health effects. When released—through maintenance work or wear and tear on the coating—it can cause serious health issues, including asthma and even lung cancer. At this industrial site, where daily maintenance is essential, it was critical to remove the contaminated coating safely and thoroughly to minimize risks to workers and the environment.

Removing chromium-6 is a dangerous and delicate process. Improper removal can release harmful particles into the air, putting workers at risk of inhalation. For the chemical plant, safety and environmental impact were top priorities, making it imperative to execute this task with precision and care.

Why did the chemical plant choose Pinovo?

The chemical plant selected Pinovo tools due to our proven expertise in safe surface preparation within ATEX environments. We understand the risks associated with chromium-6 and deliver safe, certified solutions for removing contaminated coatings. With specialized tools like Pinovo’s Picopipe, we offered a solution that met the strictest safety and environmental standards.

Explore our ATEX-certified blasting tools for contamination-free blasting. Contact us today!

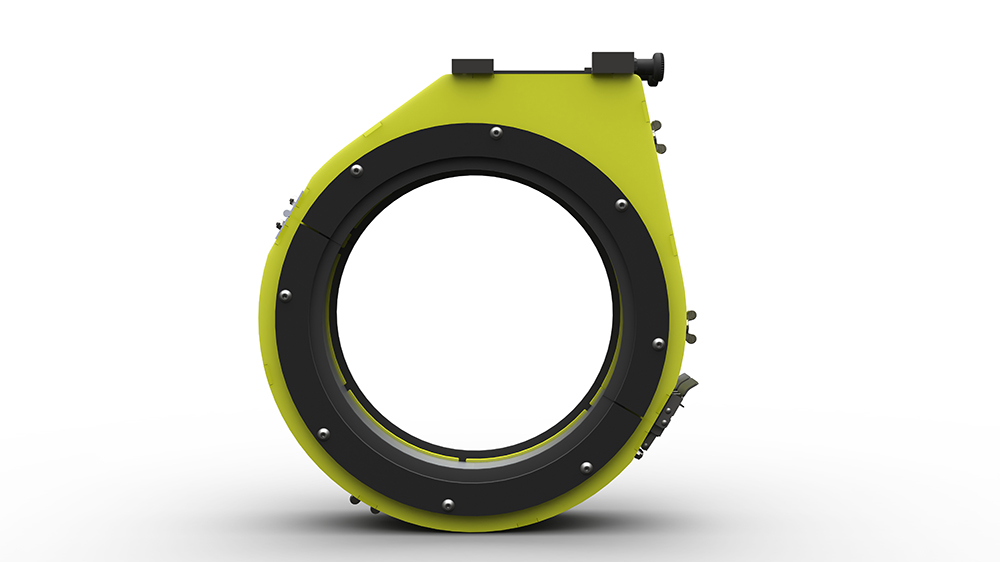

The solution: Picopipe – an innovative, safe cleaning tool for pipelines

For this project, we deployed Pinovo’s Picopipe, a tool specifically designed for blasting pipelines ranging from 3/4″ to 8″ in diameter. The Picopipe offers unmatched control and precision, allowing us to clean every inch of the pipeline, including bends, effectively. For larger bends, we used a slightly bigger tool to ensure every area was thoroughly cleaned. This method ensured that no chromium-6 particles were released into the environment, protecting both workers and the surrounding area.

The Picopipe’s dust-free technology was crucial. Its localized and targeted cleaning capability allowed for the safe removal of contaminated coatings without spreading harmful substances. This ensured that the contractor could work efficiently while maintaining the highest safety standards. As a result, the project was completed successfully and safely.

Discover how PicoPipe ensures safety and precision. Request a demo of call us directly

The result? Safe removal of chromium-6 and risk elimination

The natural gas pipelines were entirely cleaned using the Picopipe. All traces of chromium-6 were safely and thoroughly removed, effectively eliminating risks to workers and the environment. The pipelines are now safe for use, with no threats posed to the surrounding area. This successful approach ensured that the project met the plant’s high safety and environmental expectations.

Do you face contamination challenges like chromium-6? Pinovo provides safe, certified ATEX tools for addressing your toughest challenges. Contact us today for expert advice and discover how Pinovo’s products can protect and secure your industrial sites.