Dust-free deck repair on Fred Olsen Windcarrier

Challenge: The Bold Tern, a Fred Olsen Windcarrier vessel, required urgent maintenance due to corrosion and wear on its steel decks. These issues not only jeopardized the structural integrity of the deck but also posed a safety risk for the crew during operations. The challenge was to perform effective rust and coating removal while ensuring minimal environmental impact, especially given the vessel’s offshore nature and strict maritime regulations. Traditional open blasting methods were not an option due to dust generation, waste management complications, and the risk of contaminating sensitive marine environments.

Facing similar challenges with your offshore maintenance? Contact our team today to learn how Pinovo’s solutions can help you achieve efficient, eco-friendly results.

Solution: Pinovo’s closed-loop vacuum blasting system

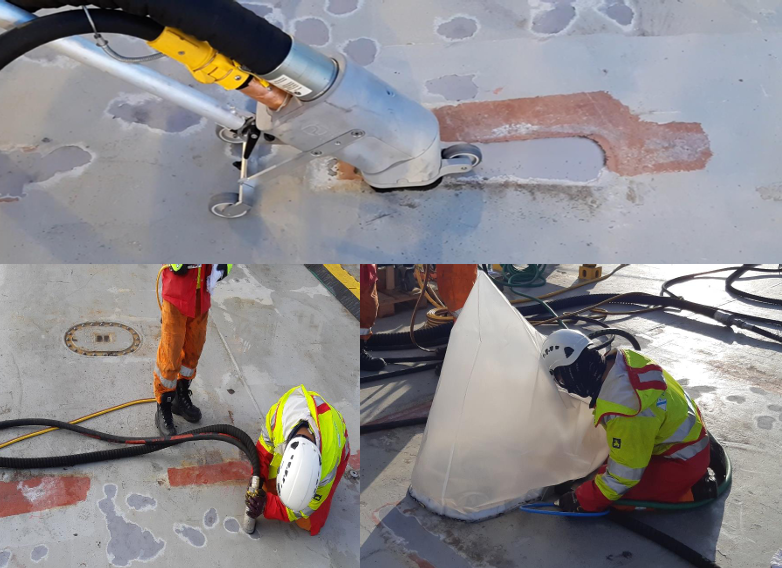

Fred Olsen Windcarrier partnered with Pinovo to address this challenge using our PiSys 100 closed-loop vacuum blasting system. This advanced technology offered a dust-free, efficient, and environmentally responsible method for deck repair. Key components of the solution included:

- Closed-loop technology: Waste material, including rust and paint, was captured immediately during the blasting process, ensuring no debris escaped into the environment.

- HEPA filtration: Provided an added layer of environmental protection, trapping microscopic particles and preventing emissions.

- Recyclable blast media: Abrasive materials were reused multiple times, reducing overall waste and cutting project costs.

- Compact and portable design: The system’s lightweight and mobile configuration allowed for easy use in confined spaces and challenging offshore conditions.

During the project, the Bold Tern crew underwent a comprehensive training program led by Pinovo specialists, ensuring they could operate the system efficiently and safely in future maintenance tasks.

Why Pinovo for offshore maintenance?

Pinovo’s solutions are ideal for offshore environments due to their unique capabilities:

- Environmental compliance: The closed-loop system meets strict maritime environmental regulations by preventing the release of harmful waste and emissions.

- Safety-first design: Dust-free blasting minimizes risks for both operators and the environment, ensuring safer working conditions.

- Efficient performance: The system’s precision tools allow for targeted blasting, reducing the time and resources required for maintenance.

- Cost-effectiveness: Reduced blast media consumption and waste management costs make Pinovo a financially attractive option.

Results: sustainable and efficient deck maintenance

Pinovo’s system delivered impressive results during the Bold Tern’s deck repair project:

- Effective corrosion removal: The steel deck was restored to optimal condition, ready for new coatings.

- Zero environmental impact: All waste was contained, eliminating the risk of marine contamination.

- Improved crew autonomy: The onboard team gained the skills to perform future maintenance using Pinovo’s system, reducing the need for external contractors.

- Reduced waste: The reusable blast media significantly minimized hazardous waste, supporting Fred Olsen Windcarrier’s sustainability goals.

Pinovo: your partner in offshore maintenance

Pinovo specializes in providing innovative, environmentally friendly maintenance solutions for the maritime and offshore industries. Our closed-loop vacuum blasting systems are designed to meet the unique challenges of offshore environments, ensuring compliance, safety, and efficiency.

Is your vessel in need of sustainable maintenance?

Contact us today to discuss your project requirements or schedule a demo. Let Pinovo help you achieve safer, cleaner, and more efficient operations offshore.